Menu

Training Courses

Business Management

We offer a comprehensive range of Business Management courses designed to equip professionals with the knowledge and skills necessary to succeed in today’s dynamic business environment. Whether you’re looking to enhance your leadership abilities, improve strategic decision-making, or manage business operations efficiently, our expert-led training programs cover a variety of essential topics. Explore our diverse selection of courses in business management and take the next step in advancing your career.

Health & Safety

We provide a wide range of Health and Safety courses aimed at ensuring a safe and compliant workplace for professionals across various industries. Our expert-led programs are designed to equip you with the skills and knowledge needed to identify risks, implement safety measures, and foster a culture of safety within your organization. Whether you are looking to enhance your qualifications or improve safety protocols, our Health and Safety courses are tailored to meet industry standards and regulations.

Engineering and Technical

We offer a comprehensive selection of Engineering and Technical courses designed to equip professionals with the technical expertise and practical skills needed to excel in today’s rapidly evolving industries. Our programs are tailored to meet the demands of various engineering fields, from fundamental concepts to advanced technical solutions. Whether you’re looking to enhance your technical proficiency or stay ahead of the latest industry trends, our expert-led courses will help you achieve your career goals.

ICT, Cloud and Security

We provide a diverse range of ICT, Cloud, and Security courses designed to equip professionals with the cutting-edge skills required to thrive in the rapidly advancing world of technology. Our programs cover a wide spectrum of topics, from foundational IT concepts to specialized areas such as cloud computing, cybersecurity, and network management. Whether you are looking to advance your career in IT infrastructure, secure digital environments, or harness the power of cloud technologies, our expert-led courses are tailored to meet industry needs and prepare you for the challenges of the future.

Digital Transformation

Sensible integration of technology into business is the Digital transformation. It touches all aspects of human life and society from daily life utilities, education, jobs, managing financials, transportation, health-care, communication and approximately everything.

Cloud Adoption

Cloud Adoption is a strategic move by organizations of reducing cost, mitigating risk and achieving scalability of database capabilities. Cloud adoption may be up to various degrees in an organization, depending on the depth of adoption. Hence there is a need for compliance assessment during cloud adoption.

AI, Blockchain & IOT

As a leading artificial intelligence company, Orient MCT helps businesses in various industries achieve higher productivity and fuel business growth with automation, machine learning, smart recognition and more.

IT Governance, Risk & Compliance

GRC is a flagship practice at Orient MCT. Think of GRC as a structured approach to aligning IT with business objectives, while effectively managing enterprise risk and meeting compliance requirements.

Our Consulting Company offer innovative, pragmatic solutions for your business needs. Our approach revolves around flexibility, accountability and an expert service that allows you to concentrate on your core business.

ADOSH & Legal Compliance

ADOSH SF is a management tool that integrates Occupational Health and Safety management components of a business into one coherent system. The integration of these components allows the business to achieve its objectives efficiently by managing the impacts of various activities and minimizing workplace risks.

QHSE Management System

QHSE management system can help to improve the quality of processes and products, control environmental impact to promote sustainability and ensure the health and safety of workers. QHSE places an emphasis on incremental improvement, communication, and reducing occupational risks. QHSE aims at building health and safety arrangements that are compatible with all places of work.

Sustainability Services

Sustainability, the long-term viability of a community, set of social institutions, or societal practice. In general, sustainability is understood as a form of intergenerational ethics in which the environmental and economic actions taken by present persons do not diminish the opportunities of future persons to enjoy similar levels of wealth, utility, or welfare.

Business Continuity & Resilence

OSHAD SF is a management tool that integrates Occupational Health and Safety management components of a business into one coherent system. The integration of these components allows the business to achieve its objectives efficiently by managing the impacts of various activities and minimizing workplace risks.

Featured Recent Projects

The partnership produce transformational results

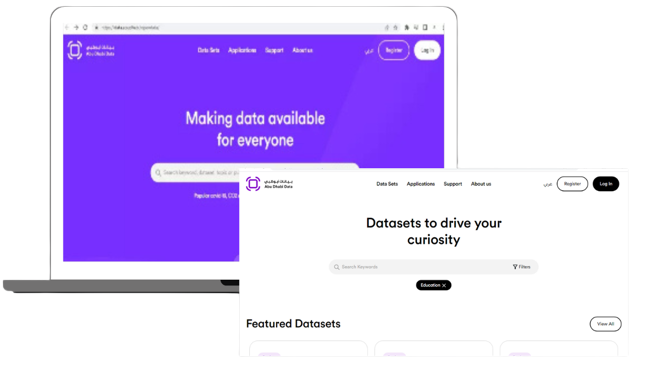

Abu Dhabi Data

We proudly became part of Abu Dhabi government data management initiative and developed the gateway website to access all data related initiatives such as: Open Data, Data Market Place, Geospatial Data etc

Abu Dhabi Open Data

Abu Dhabi Open Data Platform is revamped and managed by OrientMCT. It offers curated public data assets. enabling everyone to harness their value and wealth.

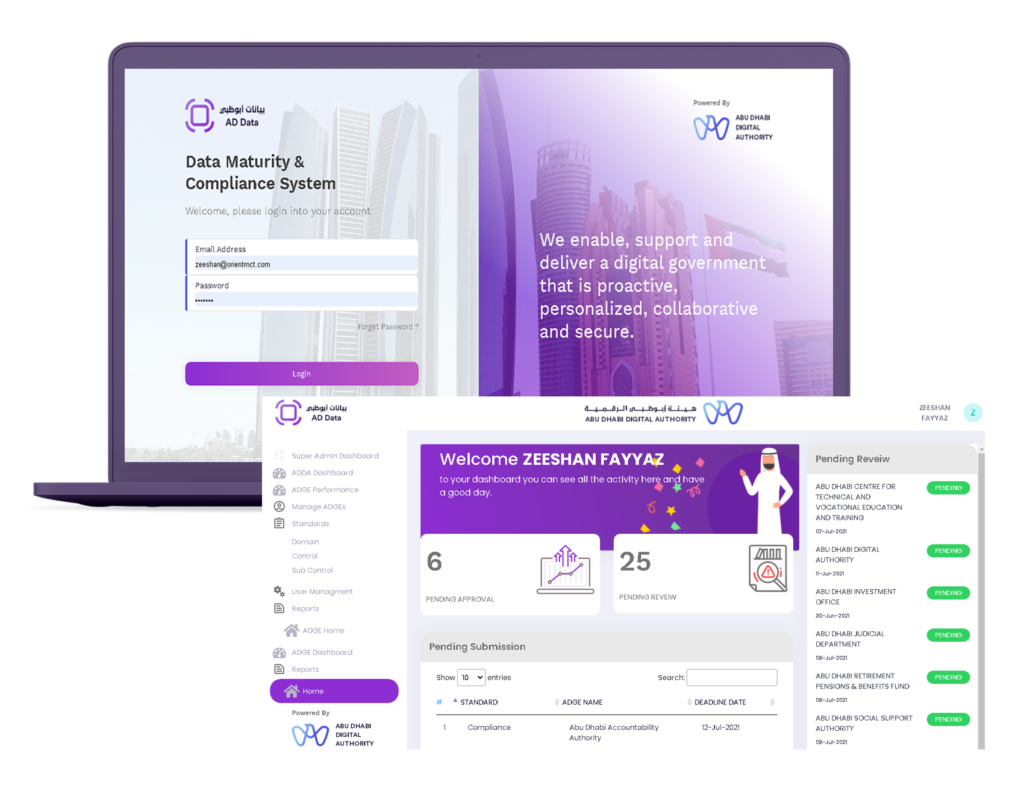

ADDA Data Maturity & Compliance System

We offer innovative, pragmatic solutions for your business needs. Our approach revolves around flexibility, accountability and an expert service that allows you to concentrate on your core business.

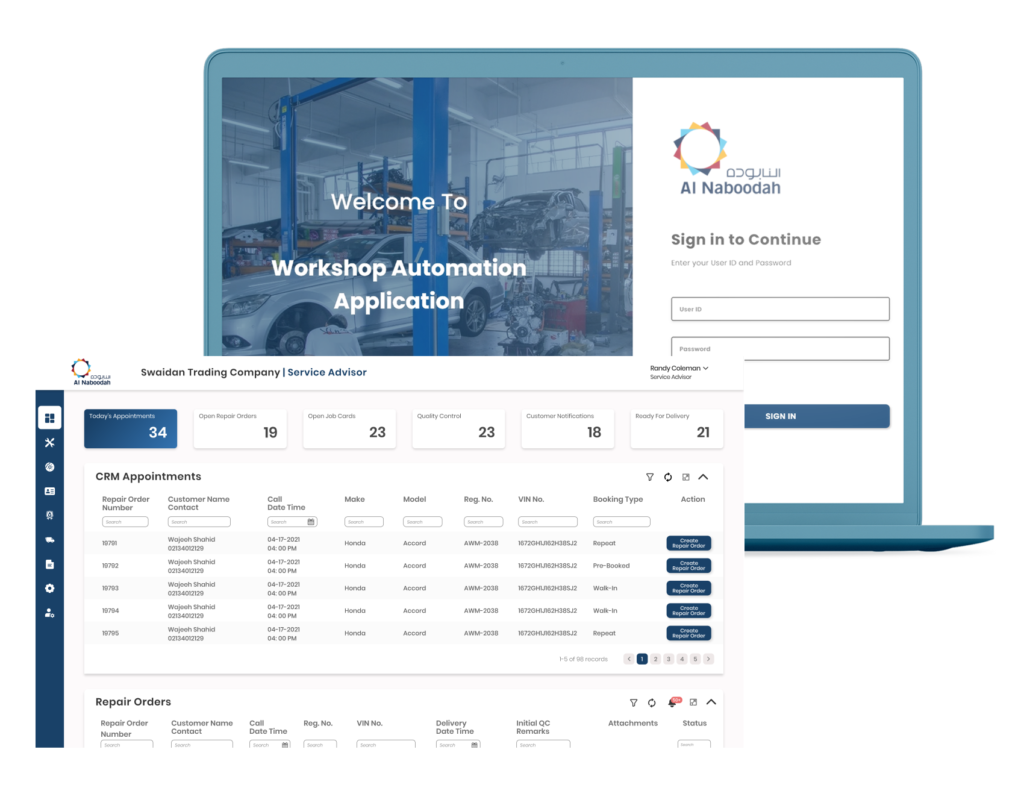

Al Naboodah Workshop Automation

Developing application for Al Naboodah Automobile division aims to digitize its services operation by providing state of the art application to its staff for improving productivity & efficiency

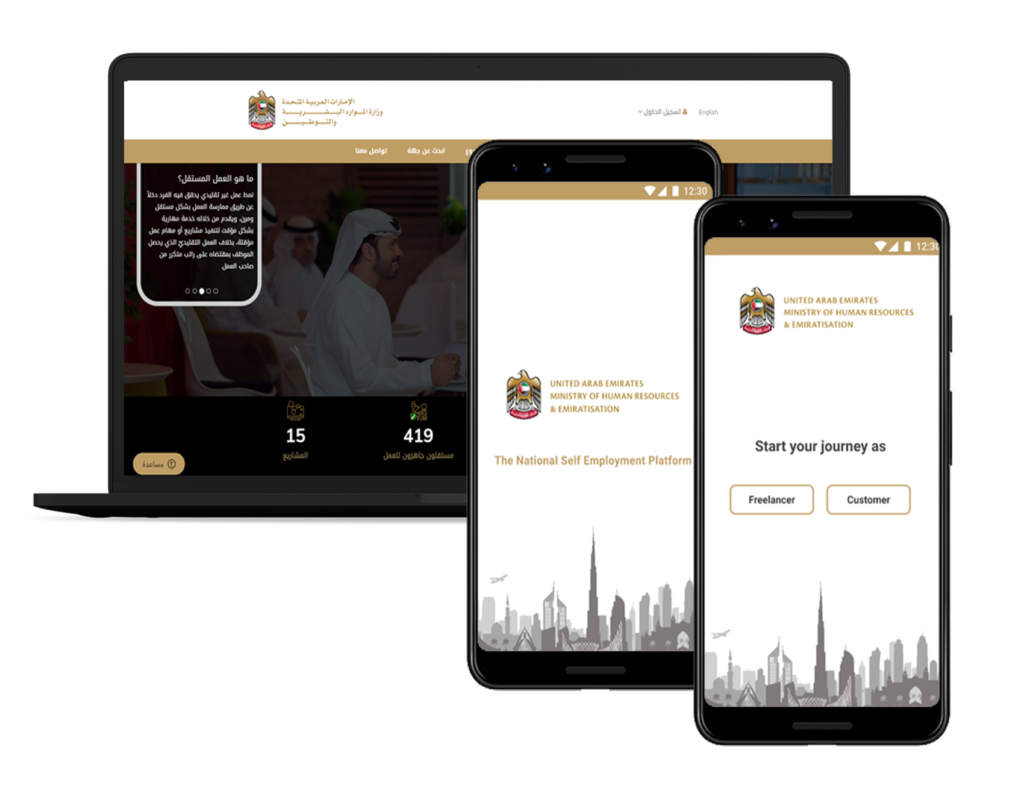

Freelancers Mobile App. for MOHRE & EF

National Self Employment Platform developed for Emirati youth to showcase their skills Online by Emirates Foundation & MOHRE

VSigns - Business Health Monitor

Diagnose your Business Health over 07 vital signs and 35 health markers to achieve success

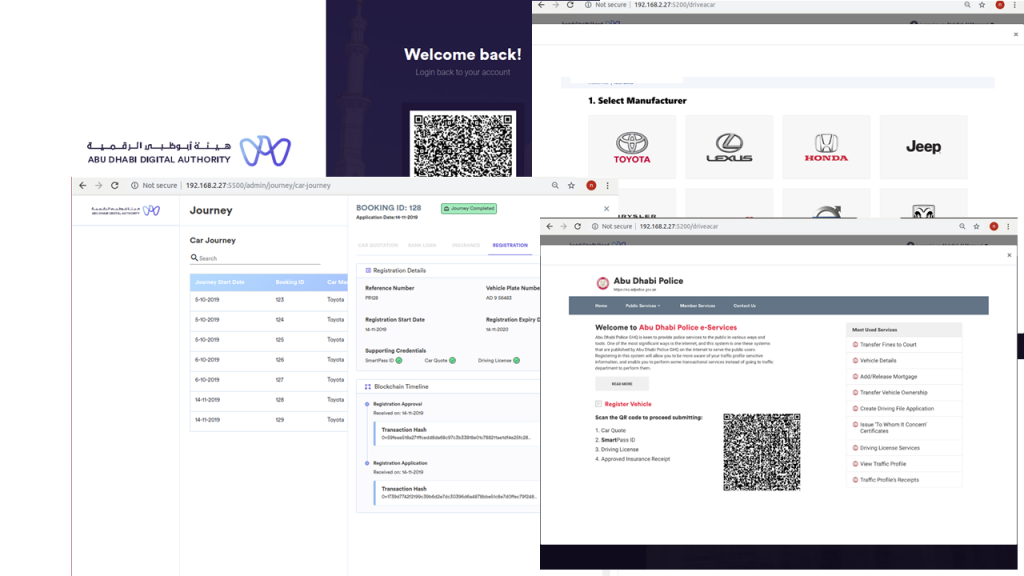

Blockchain Car Buying Journey

Developed Car buying journey POC on blockchain for ADDA (Abu Dhabi Digital Authority)

Awards Application for Dubai Immigration

Excellence Awards application for GDRFA (General Directorate of Residency & Foreigners Affairs) – Dubai

VSigns - Business Health Monitor

Diagnose your Business Health over 07 vital signs and 35 health markers to achieve success

Latest Blogs

Our Major Clients