Menu

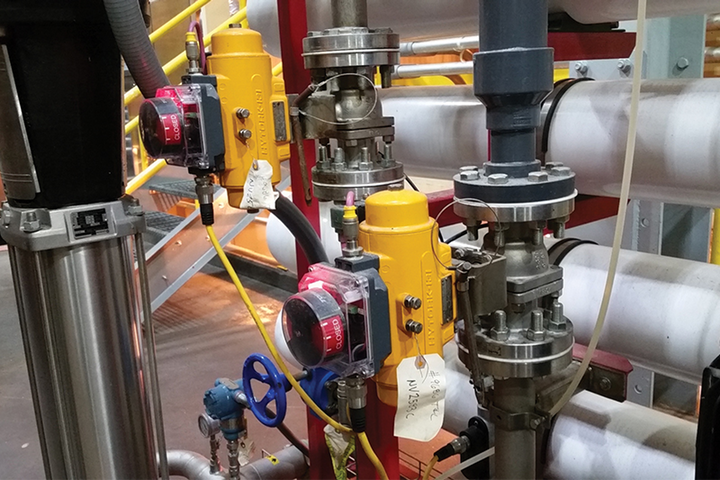

The Check Valves Training Course covers fundamental principles, types, applications, and maintenance practices related to check valves. Through a blend of theoretical learning and practical demonstrations, participants will gain a thorough understanding of how check valves function within various industrial and commercial contexts.

- Understand the purpose and importance of check valves in fluid systems.

- Identify different types of check valves and their respective applications.

- Learn selection criteria based on system requirements and operating conditions.

- Acquire knowledge of installation, operation, and maintenance best practices.

- Gain insights into troubleshooting common issues related to check valves.

- Introduction to Check Valves

- Types of Check Valves

- Applications of Check Valves

- Selection Criteria

- Installation and Maintenance

- Troubleshooting and Common Issues

Upon completion of the course, participants will:

- Demonstrate a comprehensive understanding of check valves and their functionalities.

- Be able to select appropriate check valves based on system requirements.

- Apply best practices for installation, operation, and maintenance.

- Troubleshoot common issues effectively, ensuring optimal performance of check valves in various applications.

- Engineers and technicians involved in designing and maintaining fluid systems.

- Procurement professionals responsible for selecting valves.

- Maintenance personnel seeking to enhance their knowledge of check valves.

- Students and individuals looking to enter the field of fluid systems.

Enroll Now

Ready to enhance your expertise in check valves? Visit our course registration page or contact our course coordinator at Info@orientmct.com

Frequently Asked Question (FAQ)

A check valve is designed to allow flow in one direction and prevent reverse flow, ensuring fluid system efficiency and safety.

Types include swing check valves, lift check valves, ball check valves, and piston check valves, each suitable for specific applications.

Selection factors include flow rate, pressure conditions, fluid type, and installation orientation, among others.

Regular inspection for wear, cleaning of internals, and checking of sealing surfaces are essential for maintaining optimal valve performance.

Check for debris or damage to sealing surfaces. Cleaning or replacing affected parts may be necessary to resolve leaks effectively.

Get In Touch!

Contact us for a quote or in case of any urgent queries please send us an email on: info@orientmct.com

we will get back to you right away!